Plastic Product Design

Design of all types of plastic products.

Bring your products to life

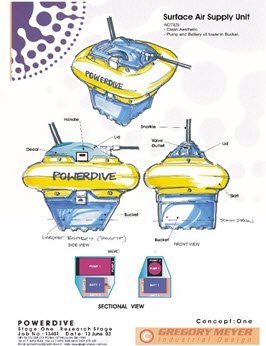

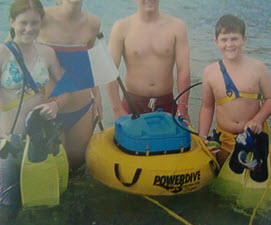

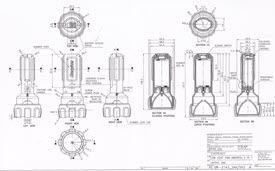

Plastic Product Design can occur in a number of ways and is dependant on the size, quantity and budget you have in mind. It is possible for instance to die cut simple membrane controls or gaskets. Vacuum formed products are very popular for point of sale displays. As the customer develops more complicated parts there maybe a necessity to develop tooling for larger items such as bins, docking modules or tanks. Typically rotor moulding is utilised here, however these products tend to be quite heavy. Injection Moulding is perhaps the most expensive process for producing parts for short runs however the detail of the parts-product are exquisite.

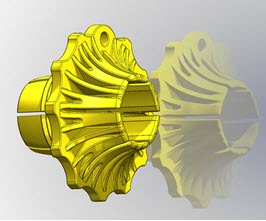

Be mindful that Plastic sheets, just like steel, can be fabricated into complex large parts or products. Dependant on the end use and budget, this can be quite primitive or executed with highly finished welded edges. It is also possible to break press, glue and machine plastic tubes or billets into gears or even sight glasses. The application of plastic material technology is only limited by your imagination and be mindful a lot of these products can be designed to be re-cycled for end of life.